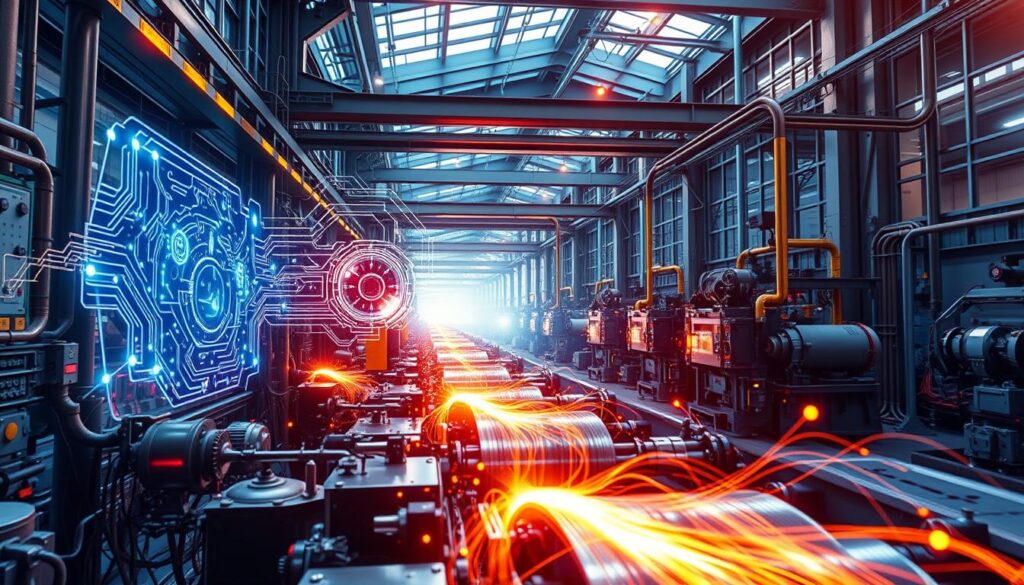

The steel manufacturing industry is on the verge of a revolution, thanks to quantum computing. This technology aims to optimize complex processes and enhance efficiency. By leveraging quantum mechanics, steel producers can overcome challenges that classical computers can’t handle. This leads to better product quality and cost savings.

Quantum computing uses superposition and entanglement to perform massive calculations. In steel production, it enables the optimization of various processes, from sourcing raw materials to assembling the final product. Quantum computers can handle a vast number of variables at once. This allows them to find optimal solutions that reduce waste, lower energy use, and improve operations.

The benefits of quantum-enhanced optimization in steel manufacturing are vast. Quantum technologies can make steel production more efficient, boosting productivity and profits. Additionally, quantum computing can help create new, advanced steel alloys. This opens up new market opportunities and drives growth.

As quantum computing advances, its role in shaping the steel industry’s future becomes clearer. By adopting this technology, steel manufacturers can lead in innovation and gain a competitive edge globally.

The Potential of Quantum Computing in Steel Production

The steel industry is on the cusp of a revolution with quantum computing. Quantum algorithms can optimize production processes, enhancing energy efficiency and reducing waste. This technology could transform steel production, from raw materials to the final product.

Quantum computing’s most promising role is in process optimization. It can analyze vast data sets to find efficiency gains. By tweaking parameters like temperature and chemical composition, it reduces energy use and waste. This makes production more sustainable and cost-effective.

Quantum computing also excels in developing new steel alloys. It simulates material behavior at the atomic level, discovering alloys with superior strength and durability. This could lead to the creation of high-performance steels for various industries.

Quantum computing’s benefits extend beyond process optimization and alloy development. It can optimize supply chains, reducing transportation and inventory costs. It also predicts and prevents equipment failures, boosting productivity.

As the steel industry digitizes, quantum computing’s role will grow. By leveraging quantum algorithms, producers can achieve unmatched efficiency and innovation. This positions them at the industry’s forefront.

Quantum Algorithms for Optimizing Steel Manufacturing Processes

Quantum algorithms are poised to transform the steel manufacturing sector by enhancing complex processes and boosting efficiency. Quantum annealing stands out as a key application, tackling intricate optimization challenges. It leverages quantum mechanics to determine the ideal temperature and pressure for steel production. This results in better quality and lower energy use.

Quantum algorithms also shine in process simulation and predictive maintenance. They can sift through vast data from sensors and other sources, creating precise simulations of steel production. This capability helps spot potential issues early, enabling timely maintenance and reducing downtime.

In the realm of supply chain optimization, quantum algorithms play a crucial role. They analyze complex networks and pinpoint bottlenecks, offering insights for smoother material and product flow. This leads to cost savings and operational efficiency.

Several quantum algorithms are particularly relevant for steel manufacturing optimization:

- Quantum Approximate Optimization Algorithm (QAOA)

- Variational Quantum Eigensolver (VQE)

- Quantum Boltzmann Machines (QBMs)

- Quantum Support Vector Machines (QSVMs)

As quantum computing evolves, we can expect even more advanced algorithms tailored for the steel industry. These will likely combine quantum annealing, machine learning, and other quantum techniques. This will further refine process efficiency and product quality.

Real-World Applications of Quantum-Enhanced Steel Manufacturing

Quantum computing advancements are driving steel manufacturing companies to adopt these technologies. Early adopters are seeing significant benefits, as shown in recent case studies. They are gaining a competitive edge and moving towards sustainable production in the steel sector.

A major European steel manufacturer successfully implemented quantum algorithms. This led to a 15% increase in production capacity without extra investment. It showcases quantum technology’s potential to enhance operational efficiency.

An Asian steel producer used quantum computing to cut energy consumption by 12%. This reduction in energy use saved costs and helped meet sustainability goals. It made the company a leader in eco-friendliness.

Quantum-enhanced optimization is not just for large manufacturers. Small and medium-sized enterprises (SMEs) in the steel sector are exploring these technologies. A European SME consortium showed how quantum algorithms can optimize steel alloy composition. This resulted in steel with better mechanical properties, giving them a market advantage.

As more steel manufacturers see the value of quantum-enhanced optimization, adoption will grow. This will lead to more efficient production, cost savings, and a greener steel industry. Quantum computing is set to transform the steel industry, bringing innovation and growth.

Challenges and Limitations of Implementing Quantum Technologies in Steel Industry

Quantum computing holds great promise for the steel industry, yet its adoption faces significant hurdles. The main technological barrier is the need for specialized hardware. This hardware must maintain the fragile quantum states required for computation. Currently, it’s pricey and demands precise environmental conditions, making it hard for many steel producers to integrate it.

Scalability is another major obstacle. As the number of qubits grows, so does the complexity of keeping coherence and managing noise. This is a significant challenge for steel manufacturers aiming to leverage quantum computing for optimizing large-scale processes.

Workforce training is crucial for the successful integration of quantum technologies in the steel industry. Quantum computing demands a unique blend of physics, mathematics, and computer science expertise. Steel producers must invest in training to equip their teams with the skills needed to operate quantum systems efficiently.

Cybersecurity is a pressing concern with quantum computing. Quantum computers can solve complex problems but also threaten many current encryption systems. Steel manufacturers must proactively develop and deploy quantum-resistant security measures to safeguard their data.

Despite these challenges, the advantages of quantum computing in the steel industry are too compelling to overlook. By tackling these limitations head-on and investing in the right resources and training, steel producers can be at the forefront of the quantum revolution.

Future Outlook: The Next Decade of Quantum Computing in Steel Manufacturing

Quantum computing is set to revolutionize the steel manufacturing industry over the next decade. The benefits of using quantum technology to optimize steel production are clear. It promises to boost efficiency, cut costs, and improve steel quality. Ongoing research will lead to more advanced quantum algorithms and hardware, making complex manufacturing processes even more efficient.

Strategic partnerships between steel makers and quantum tech providers will be key. These collaborations will help create quantum solutions tailored to steel production’s unique needs. Together, industry leaders and quantum experts can speed up the adoption of quantum optimization. This will drive innovation throughout the steel manufacturing value chain.

The steel industry’s future is quantum, and the transformation will be profound. Quantum-optimized processes will produce stronger, more durable, and sustainable steel. The efficiency and cost savings from quantum optimization will also make steel manufacturers more competitive globally. Those who invest in quantum technology now will be at the forefront of this change, securing their competitive edge for years to come.

Very interesting and eloborate scope and vision for development of Quantum computing for crucial steel processes

Would like know more details of Guidance for Infrastructure development for successfull implementation